What Does Batching Mean In Shipping: Making Shipments Smarter

Moving things from one spot to another, especially in today's busy world, can feel like a big puzzle. There are so many moving pieces, so many packages to get out the door. Just as we figure out the right words to use, like when to say "do" and when to say "does" to make our thoughts clear, businesses also need to figure out the right terms and ways to make shipping work well. It's about getting things where they need to go without too much fuss, you know?

For anyone sending out products, whether it's a small online shop or a huge warehouse, getting items ready and sent off can take a lot of time and effort. People often look for smarter ways to handle all these tasks. One idea that comes up a lot is "batching" in shipping. It sounds a bit technical, doesn't it? But, in a way, it’s a simple idea that can make a real difference.

This idea of batching, so, it’s really about grouping things together to make a job easier. It helps businesses move goods in a way that saves time and keeps money in their pocket. We're going to look closely at what this idea means for shipping, why it matters, and how it helps everyone involved. This will, hopefully, clear up any questions you might have about it.

- Isabel Beatty

- Christopher Walken Dancing Pennies From Heaven

- Nicholas Alexander Chavez Movies

- How Old Was Obama When He Became President

- Ryan Gosling Botox

Table of Contents

- What Exactly is Batching in Shipping?

- Why Does Batching Matter?

- Who Uses Batching and Why?

- Different Ways to Batch Shipments

- Getting Started with Batching

- Common Questions About Batching

What Exactly is Batching in Shipping?

A Simple Look

Batching in shipping, at its core, means gathering several orders together and processing them as one larger group. Instead of dealing with each order by itself, one at a time, you handle a bunch of them all at once. It's kind of like doing laundry; you don't wash one sock, do you? You wait until you have a full load, and then you wash everything together. That’s batching, just for packages.

This method helps to make the work flow more smoothly. You get to do the same task for many items at the same time. For example, you might print a whole stack of shipping labels all at once. Or, you might pack several boxes in a row, all going to the same area, which is pretty clever, really.

The main aim is to cut down on the times you have to switch from one task to another. Each time you stop one thing and start another, it takes a little bit of extra thought and movement. Batching helps you stay focused on one type of job for longer periods, which can be a big help, actually.

- Barack Obama Mbti

- Freaky 2

- Damon Imani View

- Tina Fey Scar On Her Face

- Is Vienna Actually Adam Sandlers Daughter

How It Works

Imagine you have ten different orders that need to go out. If you don't use batching, you might pick item one for order one, pack it, print its label, and then move to order two, and so on. This takes a lot of starting and stopping, you know?

With batching, the process changes a bit. You might first pick all the items for all ten orders at the same time. Then, you move to the packing station and pack all ten orders. After that, you go to the label printer and print all ten labels. This way, you do all the "picking" together, all the "packing" together, and all the "labeling" together. It's a more organized way to get things done, more or less.

This way of working is often put into practice with special computer programs. These programs can group orders based on different things, like where they are going or what kind of delivery service they need. It makes it easier to see which orders belong in which group, which is quite helpful for busy operations.

Why Does Batching Matter?

Saving Time and Effort

One of the biggest reasons businesses like batching is that it saves a lot of time. When you group tasks, you spend less time getting ready for each new order. Think about it: setting up your packing station for one box is the same amount of effort as setting it up for ten boxes if you do them all at once. So, you cut down on that setup time for each individual package, which is a big deal.

It also means fewer trips around the warehouse or packing area. If you pick all items for a group of orders at once, you walk fewer steps than if you picked items for one order, then went back for the next, and so on. This makes the whole process faster and less tiring for the people doing the work, too it's almost.

This saved time can mean that more packages get out the door each day. For businesses, this is very important because customers want their items quickly. Getting things shipped faster means happier customers, and that's always a good thing, isn't it?

Cutting Down on Costs

Time, as they say, is money. So, when you save time with batching, you're also saving money. Less time spent on each package means less money paid for the hours people are working. This can add up to some real savings, especially for companies that send out many items every day, very, very.

Beyond labor costs, batching can also help with materials. Sometimes, when you process things one by one, you might use more packing tape or extra labels than you need. By doing things in groups, you can be more careful with your supplies. This might seem like a small thing, but over many shipments, it makes a difference to the bottom line.

Also, some shipping services might offer better prices if you send a large number of packages at once, or if they are all going to the same general area. Batching helps you get to those higher numbers more easily. This means you might get a better deal on the actual delivery cost, which is a rather nice bonus, wouldn't you say?

Making Fewer Mistakes

When people do the same task over and over for a group of items, they tend to make fewer errors. Think about it: if you're constantly switching from picking to packing to labeling for each single order, your mind has to jump around a lot. This jumping can lead to mix-ups, you know?

With batching, you focus on one type of job for a longer stretch. This helps people get into a rhythm. They become more skilled at that one task, whether it's finding items or putting labels on boxes. This focused work often leads to fewer wrong items being sent or fewer labels being put on the wrong package, which is a bit of a relief for everyone.

Fewer mistakes mean fewer unhappy customers. It also means less time and money spent on fixing problems, like sending out replacement items or dealing with returns. So, in a way, batching helps keep things running smoothly and keeps everyone, both the business and the customer, a little happier.

Who Uses Batching and Why?

For Online Stores

Small online shops and bigger e-commerce businesses use batching a lot. When you get a rush of orders after a sale or during busy times of the year, it can be tough to keep up. Batching helps these businesses manage that sudden increase in work. It lets them process many orders without getting completely overwhelmed, so, in some respects, it's a lifesaver.

For a small business owner working from home, batching might mean setting aside a specific time each day to print all shipping labels at once, then packing all the boxes. This keeps their day organized and makes sure they don't miss any steps. It's a way to keep things moving even when they're handling everything themselves, more or less.

Larger online retailers use more advanced systems to batch orders automatically. They might group orders by the delivery service chosen, or by the shipping speed. This helps them get thousands of packages out the door every day in a very efficient manner. It's nearly impossible for them to work without some form of batching, actually.

For Warehouses

Warehouses are places where batching is a very common practice. They deal with huge amounts of goods coming in and going out. If they processed every single order on its own, things would slow down very quickly. So, they use batching to keep the flow of items steady and quick, virtually all the time.

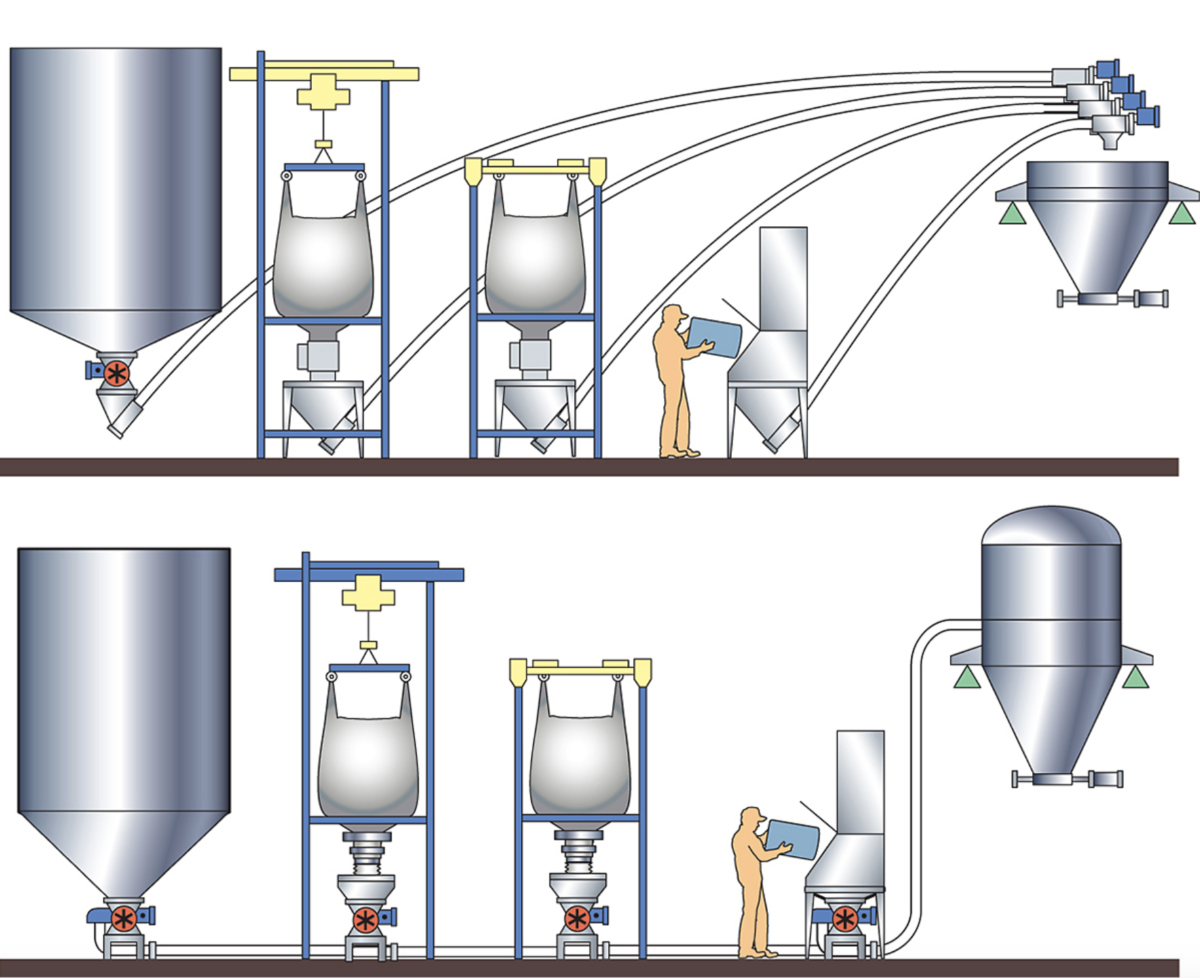

In a warehouse, batching might involve "wave picking." This means a group of workers picks all the items for a large group of orders in one go. They might use special carts or robots to help them gather everything. This way, they make just one trip through a part of the warehouse instead of many small trips, which is quite clever.

After picking, these batched items move to a packing station, where they are sorted and packed. This systematic approach helps warehouses handle a high volume of orders with fewer errors and less wasted time. It's a fundamental part of how big storage and shipping places work, apparently.

For Freight Carriers

Even the big shipping companies, the ones that move packages across countries, use batching. They group packages together based on where they are going. This is why you see trucks full of boxes heading to specific regions. They don't send a truck for just one package, do they? They wait until they have a full load going in the same general direction, just a little.

When packages arrive at a sorting center, they are quickly sorted into groups for different cities or areas. This is a form of batching. All packages for New York go into one container, all for Los Angeles into another, and so on. This makes it much easier to load them onto the right truck or plane. This sorting process is arguably what makes large-scale shipping possible.

This kind of batching helps these carriers save on fuel and time. A truck full of packages going to one place is much more cost-effective than many trucks carrying just a few items each. So, batching helps them deliver items faster and at a lower cost, which could be seen as a benefit for everyone who sends or receives packages.

Different Ways to Batch Shipments

By Destination

One very common way to group shipments is by where they are going. If you have ten packages, and five are going to the same city or region, it makes sense to handle those five together. This is because they will likely travel on the same truck or through the same sorting hub. It's a simple, yet effective, way to organize things, you know?

This method is especially good for businesses that send items all over the country or even the world. By grouping packages by their final stop, they can make sure that all items for a certain area are ready to go at the same time. This tends to make the loading and transport part of the process much smoother.

It also helps with getting better shipping rates. Sometimes, carriers give discounts for sending many packages to the same area at once. So, batching by destination can put a little extra money back into your pocket, which is a rather nice perk, really.

By Carrier

Many businesses use different shipping companies for different types of deliveries. Some might use one carrier for very quick deliveries and another for standard ground shipping. Batching by carrier means you group all the packages that will go with a specific delivery service together. This is a typical way to organize things, you see.

For example, all packages going by "Express Mail" might be processed in one batch, and all "Standard Ground" packages in another. This makes it easier when the delivery trucks come to pick up. The driver for one company only takes the packages meant for them, saving time for everyone. This usually avoids confusion at pickup, which is a good thing.

This approach helps keep your shipping station organized. You're not mixing up labels or packages meant for different companies. It helps to ensure that each package gets to the right driver, which often means fewer delays and fewer headaches, you know?

By Product Type

Some businesses find it helpful to group orders by the kind of product being shipped. For example, if you sell both small, soft items and large, fragile items, you might batch them separately. This is because they need different kinds of packing materials or different handling. It just makes sense, doesn't it?

Handling all the fragile items together means you can set up a special packing station just for them. You have all the bubble wrap and special boxes ready. Then, you can move to the next batch of, say, clothing items, which might just need a poly mailer. This kind of grouping can make packing much faster and safer for the items, too it's almost.

This method can also help with inventory control. When you're picking items for a batch of similar products, you might notice if you're running low on something more quickly. It helps keep things tidy in your stock room and packing area, which is a pretty good bonus, really.

By Order Size

Another way to batch is by how big or small the order is. You might have orders that are just one small item, and others that are many items needing a big box. Grouping these by size can streamline the packing process. It's a practical way to approach things, actually.

For small, single-item orders, you might have a fast-track packing method. You can quickly grab the item, pop it in a small mailer, and put a label on it. For larger orders, you might need more time, more packing materials, and perhaps even two people to pack it. So, separating them helps you use your resources wisely, you know?

This method helps to keep your packing stations efficient. The station set up for small items won't be held up by a huge order, and the station for big orders won't be wasting time on tiny packages. It helps maintain a steady flow of work, which is usually a sign of a well-run operation.

Getting Started with Batching

Tools and Technology

To start batching, especially for a business that sends out many items, some tools can be a big help. The most important one is often a shipping software program. These programs can connect to your online store and pull in all your orders. They can then help you sort and group those orders based on the rules you set up, which is pretty handy, really.

Many of these programs let you print shipping labels for an entire batch at once. This saves a ton of time compared to printing them one by one. Some even help you create packing slips for each batch, making sure you have all the right paperwork together. This kind of tech makes the whole batching idea much easier to put into practice, you know?

For those with very high volumes, automated systems, like conveyor belts or sorting machines, also play a part. These big machines can quickly sort packages into batches based on their labels. While this is more for very large operations, the idea is the same: use tools to group things for faster processing. You can learn more about how technology helps businesses on the Small Business Administration website.

Planning Your Batches

Before you start batching, it's a good idea to think about how you want to group your orders. Will you batch them by the delivery service, or by where they are going? Maybe you'll do it by the kind of product. The best way for your business might depend on what you sell and how many orders you get each day, very, very.

You might also want to decide when you'll create your batches. Will it be once a day, or twice? Some businesses do a morning batch and an afternoon batch. This planning helps you make sure you have enough orders in each group to make the batching worthwhile. It's a bit of trial and error at first, but you'll figure it out, more or less.

It's also good to think about your current workflow. Where do you spend the most time? Is it picking items, or packing, or printing labels? Batching can be set up to tackle those specific time-consuming parts of your process. This kind of thoughtful approach usually yields the best results, you know?

What to Look Out For

While batching is great, it's not perfect for every single situation. For example, if you get an urgent order that needs to go out right away, you might not want to wait for a whole batch to form. In those cases, you might process that one order on its own. It's about being flexible, after all.

Also, if you only get a very small number of orders each day, batching might not save you much time. If you only have two orders, grouping them might not make a huge difference compared to just doing them one after the other. It's important to find the right balance for your specific needs, you know? Learn more about shipping processes on our site, and how to optimize your fulfillment.

Sometimes, if a batch is too big, it can get a bit messy. It's like having too many ingredients for a recipe; things can get confusing. So, finding the right size for your batches is important. Start with smaller groups and see how it goes, then you can make them bigger if it makes sense. This helps you avoid new problems while trying to solve old ones, which is pretty smart, really.

Common Questions About Batching

What is a shipping batch?

A shipping batch is a group of several orders that are processed together, rather than one by one. It's a collection of packages that share some common features, like going to the same area or being picked up by the same delivery service. This grouping helps to streamline the work involved in getting them ready for transport, you know?

Why is batching important in logistics?

Batching is important because it helps businesses save time, cut down on costs, and make fewer mistakes. By doing similar tasks for multiple orders at once, it makes the whole process of moving goods much more efficient. This means products get to customers faster and with less effort, which is a very big deal in today's world, actually.

How does batching save money?

Batching saves money in a few ways. It reduces the amount of time people spend on each package, which lowers labor costs. It can also lead to better deals from shipping companies because you're sending more packages at once or to the same places. Plus, by reducing errors, it cuts down on the costs of fixing mistakes, like sending out replacement items, which is quite helpful, really.

- Fireflies Erome

- Osrs Slayer Points

- Telegram Djibouti

- Female Singers From Memphis

- Russell Westbrook Net Worth

What Does Batching Mean In Business at Marie Merritt blog

What Does Batching Mean In Business at Marie Merritt blog

Weigh Batching Systems – Digitalis Process Systems